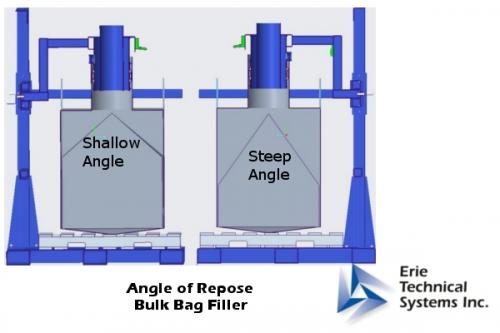

The angle of repose is dependent on a wide variety of material characteristics – density, surface properties, particle size – to name a few. Angle of repose is a significant factor in the design of a bulk bag filler. For most bulk bag filling applications, the goal is to pack as much material into each bulk bag as possible. A material with a high angle of repose has the potential to back fill into the fill head and limit the amount of material that can be placed into the bag. With these materials, vibration can be used during the filling cycle to knock down the cone on the top of the bag. This allows for filling with higher target weights and eliminates material backing up into the fill head.

Tim Porco – Erie Technical Systems Inc. – timp@erietechnicalsystems.com