Choosing the proper flexible screw conveyor for someone unfamiliar with the design and implementation of this type of conveyor can be a challenge. This article is intended as a guide to help select the right flexible screw conveyor for a project. To accomplish this, we will begin with the basic mechanical makeup of a flexible screw conveyor. We will then discuss the advantages and limitations of flexible screws. With this understanding as the basis, the second part of the article will discuss the information needed to properly specify a flexible screw. Finally, we will discuss how this information translates to the physical hardware, ensuring a worry-free deployment of a flexible screw conveyor.

What is a flexible screw conveyor and how does it work?

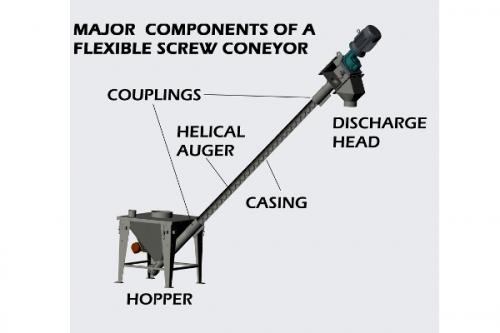

A flexible screw conveyor moves and elevates bulk material by rotating a helical shaped auger inside a casing. They are typically used to elevate powders and granular bulk materials into mixers, packaging machines or storage bins. A typical flexible screw conveyor consists of an Inlet hopper, a helical auger, the conveyor casing, couplings and a drive/discharge head as shown in Figure 1: Major components of a Flexible Screw Conveyor. They are called flexible screws because the auger portion of the conveyor is a shaftless design and the casing is typically Ultra High Molecular Weight Poly Ethylene (UHMW-PE). The spring like auger and the UHMW-PE casing allow for smaller diameter conveyors to be flexed or bent around fixed objects or to change the position of the discharge head.

What are the advantages and limitations of a flexible screw conveyor?

Flexible screw conveyors are a great way to move virtually any bulk material. It is important to understand the advantages as well as the limitations of this type of conveyor. Some of the main advantages of the flexible screw are:

- Price – Flexible screw conveyors are relatively inexpensive when compared to other traditional conveying systems.

- Flexibility – As the name implies, the casing of the smaller diameter conveyors is flexible and can be routed around fixed obstacles, unlike a belt conveyor for example.

- Ease of Cleaning – Flexible screws are generally designed to be quickly cleaned and put back into service.

- Quickly disassembled – A flexible screw can be quickly disassembled by removing the clean out cap, disconnecting the J-bolts that attach the auger and sliding the auger out the bottom of the conveyor. The casing is removed by loosening the couplings that connect it to the hopper and the discharge head. The hopper lid can easily be removed by loosening the t-bolts and rotating them out of the way.

- Good for food applications – With food grade UHMW-PE construction and 300 series stainless steel product contact surfaces, flexible screw conveyors are commonly used in food grade applications.

- Adaptability – Although different materials can require a different auger profile, this can be changed out quickly to accommodate changes in process as well as to re-purpose the conveyor.

- Few moving parts – The auger and drive shaft are the only moving parts in the product area. The motor and gearbox are isolated from the shaft so no oil can leak into the product flow path.

- Less maintenance – Flexible screw conveyors have a single bearing located at the top of the discharge head and out of the product flow path. This limit the required maintenance versus a fixed screw conveyor with a bottom bearing in the product flow path.

- Easy to change the length – Conveyors can be shortened by simply cutting the casing and auger. They can be lengthened by replacing the auger and casing with a longer section. This makes repurposing the machine easy and cost effective.

- Portability – Flexible screws are easily made portable by placing the hopper on a wheeled cart that supports the discharge head. See Figure 2: Portable Flexible Screw Conveyor. The control panel can be fitted with a power cord and plug so control is as simple as plugging it into a high voltage receptacle

Even with all these excellent features, flexible screw conveyors do have limitations and are not right for every application. It is important to understand these limitations so that the flexible screw is not misapplied.

- Not all material can be conveyed – High moisture, very dense, large solid particles and slurries are some of the products that can reduce the effectiveness of a flexible screw conveyor.

- Cannot run dry – The conveyor shouldn't run dry for extended periods of time because of excessive wear caused by the rotating auger contacting the casing.

- Cannot completely empty the casing – The conveyor will not typically empty completely at the end of cycle. Depending on the material characteristics, conveyor diameter, auger style and overall layout, the amount of residual material in the conveyor varies from about ¼ to 1 ft3 (7 to 29 liters) of material. Additionally, cleaning between runs when changing between incompatible products may be required.

- Limited length – Unlike a fixed screw where the auger is welded directly to a central shaft, a flexible screw can stretch so long lengths, typically over 40 feet, are not recommended.

What Information is needed to select the right Flexible Screw conveyor?

To select the right flexible screw conveyor for a specific application, it is necessary to collect information on the product being moved as well as the operational details for the conveyor. This information will dictate the design and components used in construction of the flexible screw conveyor as will be discussed in the next section.

The most essential information needed in specifying a flexible screw conveyor are the physical properties of the material. Powders and granular material can vary widely in their physical properties but the following items are most important:

- Product Density – What is the product bulk density in lbs./ft3 (kg/m3)?

- Particle Size – What is the average particle size distribution of the material?

- Flowability – Is them material free flowing or does it pack and bridge? Does the material smear?

- Abrasiveness – Extremely abrasive materials will wear the standard UHMWPE casing and a metal casing may be required.

- Aeration – Does the material aerate easily and create dust?

Once you consider the physical characteristics of the material to be moved, the next step is to review the operational requirements.

- Discharge Rate – What is the desired flow rate in lbs./hr (kg/hr)?

- Discharge Height – How high from floor level does the material need to be moved?

- Layout – Typically flexible screw conveyors have a 45-degree discharge angle so the inlet hopper will be located the same distance away from the discharge as the discharge height. Are there any obstacles in the path between the inlet hopper and the discharge point?

- Frequency – How often will the screw conveyor run? Is it continuous or intermittent duty?

- Utilities – What power is available at the installation location? Is compressed air readily available and at what pressure and flow rate?

- Controls – Is a simple on/off pushbutton sufficient or will the process require a variable speed with interlocks for starting and stopping of the conveyor?

What hardware is needed based on the application information?

For free-flowing products the basic screw conveyor setup of an inlet hopper, flat wire auger, casing and discharge head is sufficient. The conveyor size typically 2", 3", 4", 5" or 6-inch nominal will provide flow rates from 50 to 500 ft3/hour. The size of the conveyor will be selected based on the desired flow rate. The product density and length of the conveyor are then used to size the motor and gearbox for the discharge head, based on the loading.

For more challenging applications where the product does not flow freely, bridges or aerates modifications are required to the standard conveyor. Here are some of the most common modifications and the challenges addressed by each.

- Auger Selection – There are many auger profiles available in flexible screw conveyor but the most common are: flat wire auger, flat wire auger with beveled edge, round wire auger and square wire auger. See Figure 3: Common Auger Profiles. The shapes refer to the cross section of the wire itself. A flat wire auger is most efficient as the larger face moves more material up the screw conveyor for free-flowing materials under 40 lbs./ft3 (640 kg/m3). A flat wire auger with a beveled edge is a good selection for sticky materials that pack or smear. Round wire augers are used for heavier materials over 40 lbs./ft3 (640 kg/m3). Square wire augers are best for use with heavy, irregular shaped products.

- Casing Selection – The most common casing is plain UHMW-PE but options are available to address static, corrosion, wear and temperature concerns. Moving dry material through a plastic casing can produce static electricity. Enhanced conductivity casing can be provided and grounded if this presents a hazard. Solid stainless steel casing can be provided for improved wear, corrosion resistance and operation at elevated temperatures.

- Center Cores – The helical augers in a flexible screw do not have a center shaft. For certain materials, placing a center core of UHMW-PE in to occupy this space improves the throughput by preventing the material from falling back down the center of the auger. This is most commonly applied to materials that are extremely fluid and aerate.

- Hopper angles – Square hoppers are typically designed with a 60 degree sloped sides to promote flow out of the hopper. The most difficult products such as titanium dioxide which pack and smear require rounded hoppers with even steeper side walls to promote flow out of the hopper.

- Flow Aides – For materials that aerate, bridge, rathole or pack, flow aides may need to be added to the inlet hopper. There are pneumatically actuated fluidizing pads that introduce air into the product. A second common option is a rotary vibrator, which can be either electrically or pneumatically actuated. A third common addition is an electrically driven helical or paddle shaped auger mounted through the side wall of the hopper. For extremely difficult products both vibration and an auger can be employed.

Summary

Flexible screw conveyors are a low-cost method for elevating virtually any bulk material. Before specifying a flexible screw, it is important to understand the basic components and how they operate as well as the advantages and limitations. With this knowledge, a thorough review of both the material characteristics and application details will ensure that the right flexible screw conveyor is selected for the application and the flexible screw conveyor will deliver years of trouble-free service.